Applications:

Ideal for the movement of air and non-aggressive gas and vapours.

Air Handling Units (AHU), hygienic units, clean room filter units.

Cooling of electrical motors and generators (e.g. in wind parks), ventilation of switch cabinets, air conditioning (e.g. in trains).

Advantages

- Compact and space saving design with external rotor motor drive and high-performance forward-curved impeller

- Low for maintenance direct drive fans (no belt wear or belt replacement necessary)

- Various control possibilities

- Customers requirements can be met without problems

- Easy installation in any position

- Extremely low starting currents

- Motor protection through thermal contacts in motor winding

Designs:

The following design models are available:

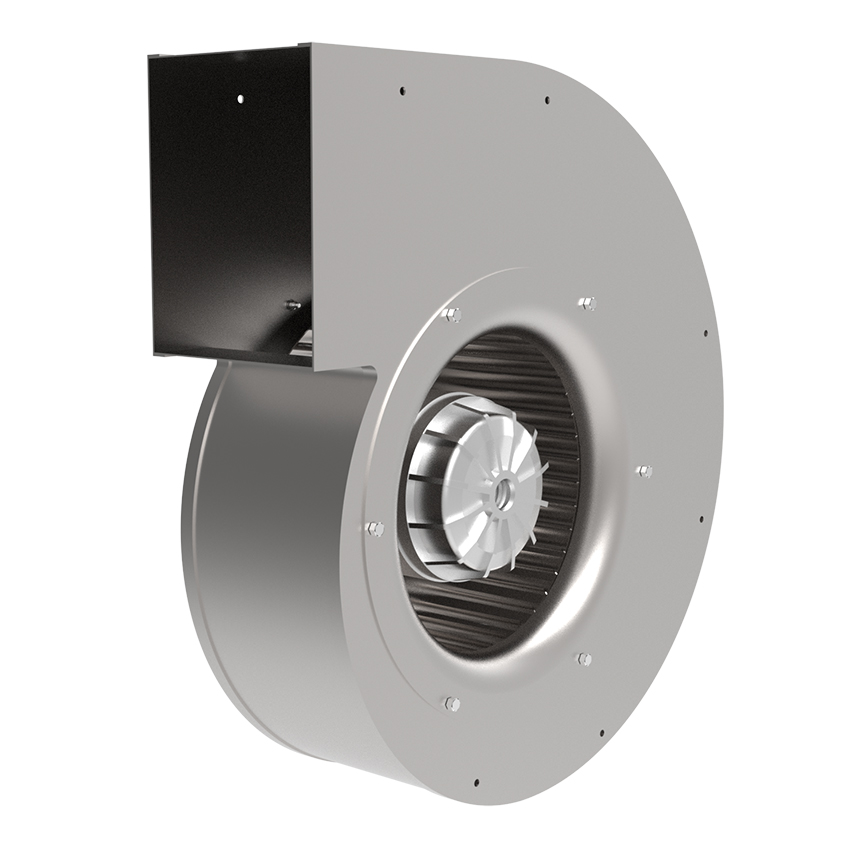

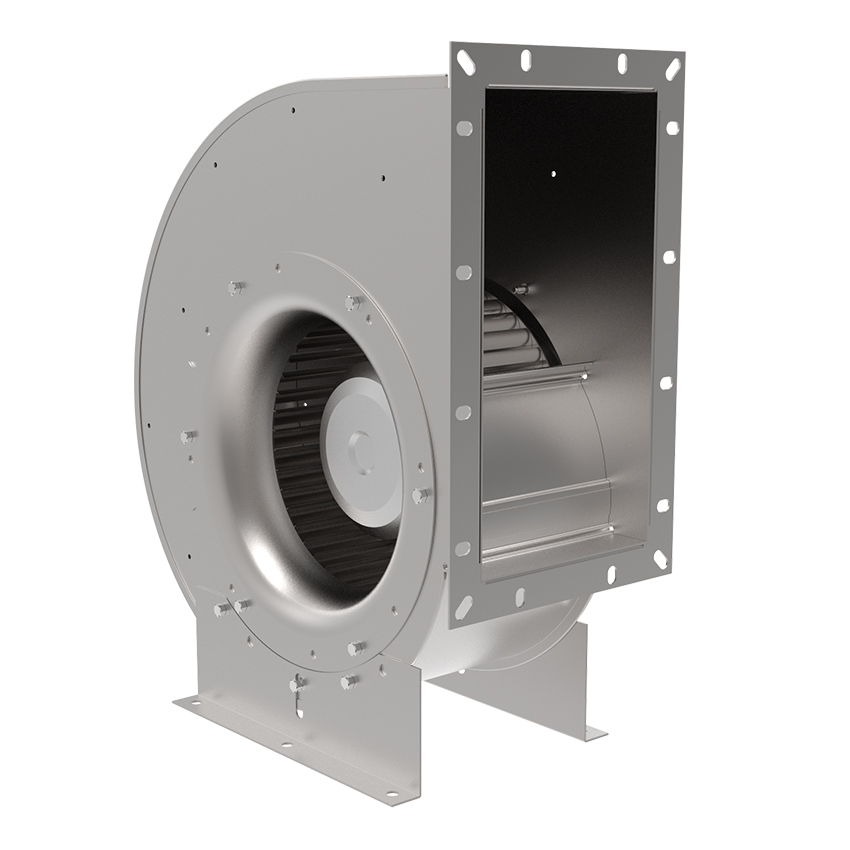

- ERAE/D: single inlet centrifugal fan

Sizes Available: 180-400 mm / 7.09-15.75”

Casings:

The casings of the high efficiency centrifugal fans are made of galvanized sheet metal.

The side parts are produced with nut sets to fix the mounting brackets, which can be fixed in steps of 90°.

Epoxy coating is available upon request.

ECOFIT series: steel painted black or plastic scroll.

Impellers:

The impellers with 38-42 forward curved blades are made of galvanized sheet metal.

They are mounted directly to the external rotor motor.

ECOFIT series: galvanized steel or plastic impeller.

The impellers are statically and dynamically balanced together with the external rotor motor according to quality level G2,5 DIN ISO 1940.

Direction of rotation:

Direction of rotation for fan types ERA is clockwise viewed from the inlet side, but for fan

types DRA it is anti- clockwise viewed from the cable outlet.

Caution: Low air volume at wrong direction of spin!

ECOFIT series: direction of rotation is indicated in the catalogue on each datasheet.

Motors:

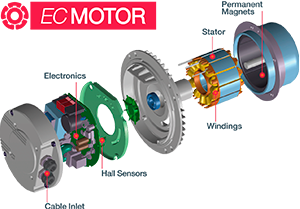

Rosenberg external rotor motors are manufactured in protection class IP54.

ECOFIT external rotor motors are manufactured in protection class IP44 or IP54 for

GDF.

The winding insulation corresponds to insulation Class F (UL - approved).

Bearings are deep groove ball type in sealed housing. Special grease lubrication

provides maintenance-free operation, low-noise and extended life.

ECOFIT series: ball bearings closed on both sides are used. Special grease lubrication provides maintenance-free operation, low-noise and extended life.

Motor protection:

All motors are equipped with thermal contacts, wired in series. Thermal contacts are temperature dependent control elements, sensing the winding temperature of the motor. These contacts protect the motor windings from overload, failure of a mains phase, and standstill of the motor and of high temperature rise to the medium ventilated.

In addition to the mounted thermal contacts we recommend the use of our motor protection control units.

Rosenberg also offers 5-step speed controllers, RTE and RTD.

Motors are equipped with the motor protection in connection with thermal contacts. An additional motor protection switch is not required.

Speed control

Speed control can be provided for fans that demand optimal adjustment of the operation point.

Speed control is obtained by “Voltage Control” and “Frequency Control”, as described below.

Voltage control: The speed control is provided by reduction of the terminal voltage. If the voltage will be reduced the speed of the motor decreases and the air volume flow sinks in proportion with the speed. The matching voltage controllers can be provided on request.

Frequency control: All voltage controllable fans for three-phase power supplies can also be speed controlled by frequency converter from 60Hz downwards. The speed control is realized by reduction of the power supply frequency. At higher frequencies than 60Hz the motor will be thermally overloaded.

With operation of the motors on a frequency controller the maximum speed of voltage increase of 500V /μs must not be exceeded. According to the frequency converter type and the length of the cable between motor and frequency converter additional components must be planned. Please refer to the operation manual of the frequency converter.

Description of Constructions: