Applications:

Air Heaters, Heat Pumps, Condensers, Cooling Units, Evaporators and Chillers

Advantages

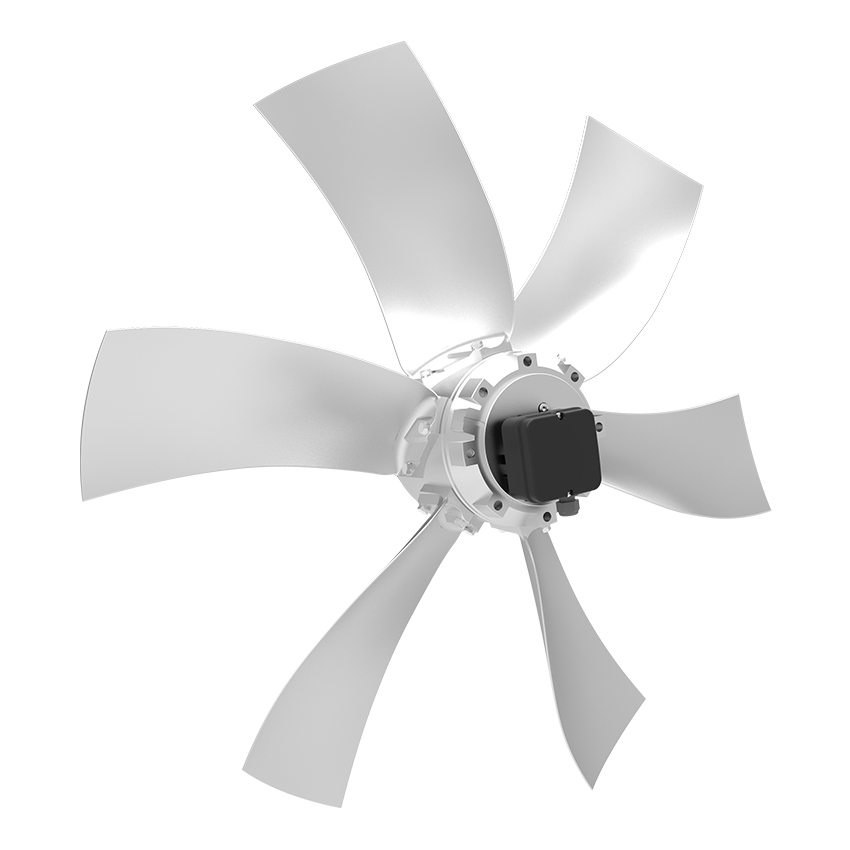

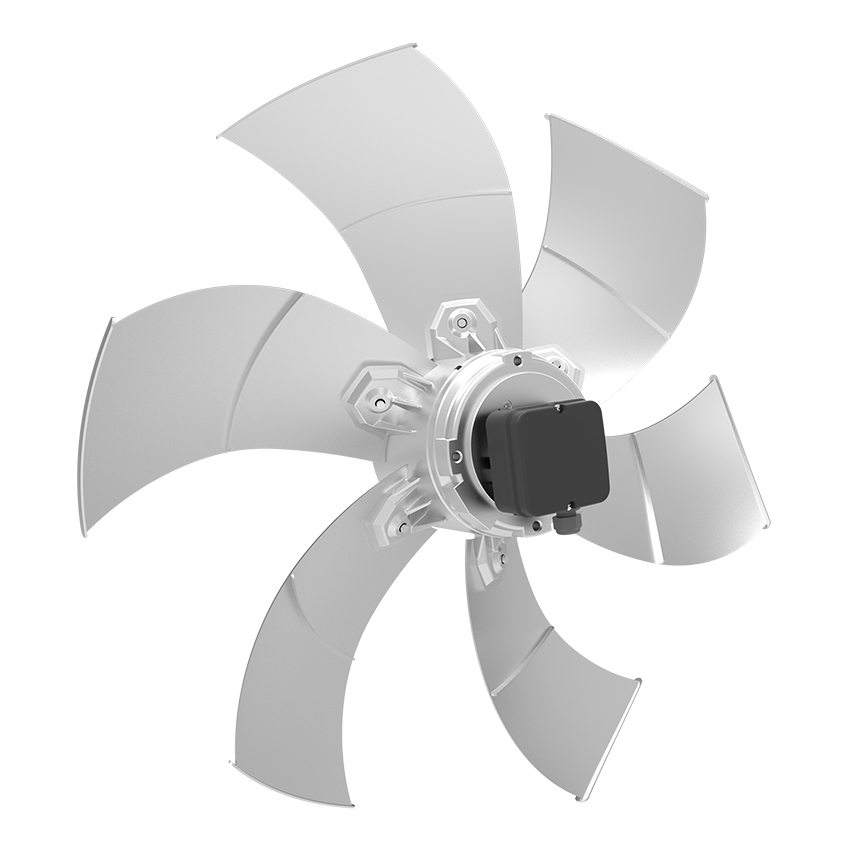

- Noise-optimized blade construction

- Constant high degree of efficiency

- Mountable in all installation positions

- A wide range of voltage- and frequency-controlled constructions

Features and Constructions

Rosenberg axial fans with improved and noise optimized blades combined with a voltage controlled AC-external rotor motor form an optimized fan unit in regard to design and air movement.

The combination of the voltage controlled Rosenberg-external rotor motors, flexible production of blades and high-end metal fabrication, gives Rosenberg the capability to manufacture fan modules that provide the best possible benefit to customers while taking the design demands and the customers application into consideration. This is done mainly with the help of the three blade angles (G, K, N), which offer a variety of solutions for various customer applications.

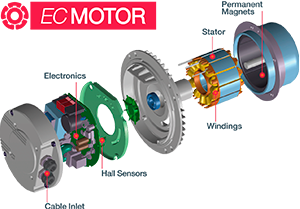

Motors

Rosenberg external rotor motors comply with protection class IP54. The winding insulation corresponds to insulation class F. Through the use of deep groove ball bearings, closed on both sides, with specially paired grease lubricant, maintenance-free and low-noise operation is guaranteed. All AC-external rotor motors can also be manufactured in UL construction, upon request.

Motor Protection

All motors are equipped with factory installed thermal contacts in the windings. Thermal contacts (TB) are temperature dependent control elements, controlling the winding temperature of the motor. If they are installed correctly, they protect the motor windings from overload, failure of a mains phase, standstill of the motor and from excessively high temperatures of the ventilated medium.

Electrical Connection

The nominal voltage indicated on the nameplate is valid with a max. allowed voltage tolerance of +/- 10%. The standard construction has mounted terminal boxes. Cable lead-out on the side is possible. The connection ends are stripped at 10 cm and supplied with end splices. Standard cable length for motor size 80 and 106 is 68 cm and for motor size 137 and 165, it is 88 cm from the motor flange. Special cable lengths are available upon request.

Voltage Types

The performance data as indicated on the performance curve charts are for the standard versions at 50Hz 1~ 230V and 3~ 400V (60Hz from page 98). Motors for special voltages or frequencies are available upon request for an additional charge.

Speed Control

The required, system-specific, optimal setting of the desired operating point can only be attained with a suitable system for speed control. There are two common systems that can be used for speed controlling fans of this series.

Voltage Control

Speed control is accomplished by reducing the terminal voltage. Using this method, the slippage is increased depending on the load and the speed is reduced. The air volume changes proportionally with the RPMs. All voltage controllable axial fans in three-phase current construction can also be speed controlled by a frequency converter from the nominal frequency on down.

Frequency Control for three-phase fans

Speed control is accomplished by reducing the frequency through the use of a frequency converter. The cut-off frequency, adjustable on the frequency converter, is 50Hz for all fans.

With fans from the 60Hz list (starting on page 98), the frequency is 60Hz. Each performance curve shows the max. frequency possible. With frequencies higher than the rated frequency the motor will thermally overload. For emergency operation or upon failure of the frequency converter, all frequency controllable types can also be used directly with 400V on the 50Hz or 60Hz mains supply.

When operating the motors using a frequency controller the max. rate of voltage increase of 500V/µs must not be exceeded.

Depending on the frequency converter type and the length of the cable between motor and frequency converter additional components may be required (sine filter).

Single phase fans may not be operated on a frequency controller.

Reference to Directives

Rosenberg AC axial fans meet in their design the EMV-Directive EMV 2014/30/EU, Low Voltage Directive 2014/35/EU, and ErP Directive 2009/125/EC.

UL Component Recognition

Almost all motors, which are used in the 60Hz fan types, are UL / CSA recognized. These types are marked on the respective pages with the „Recognized Component Mark“.

Additional products have to be checked for specific projects.

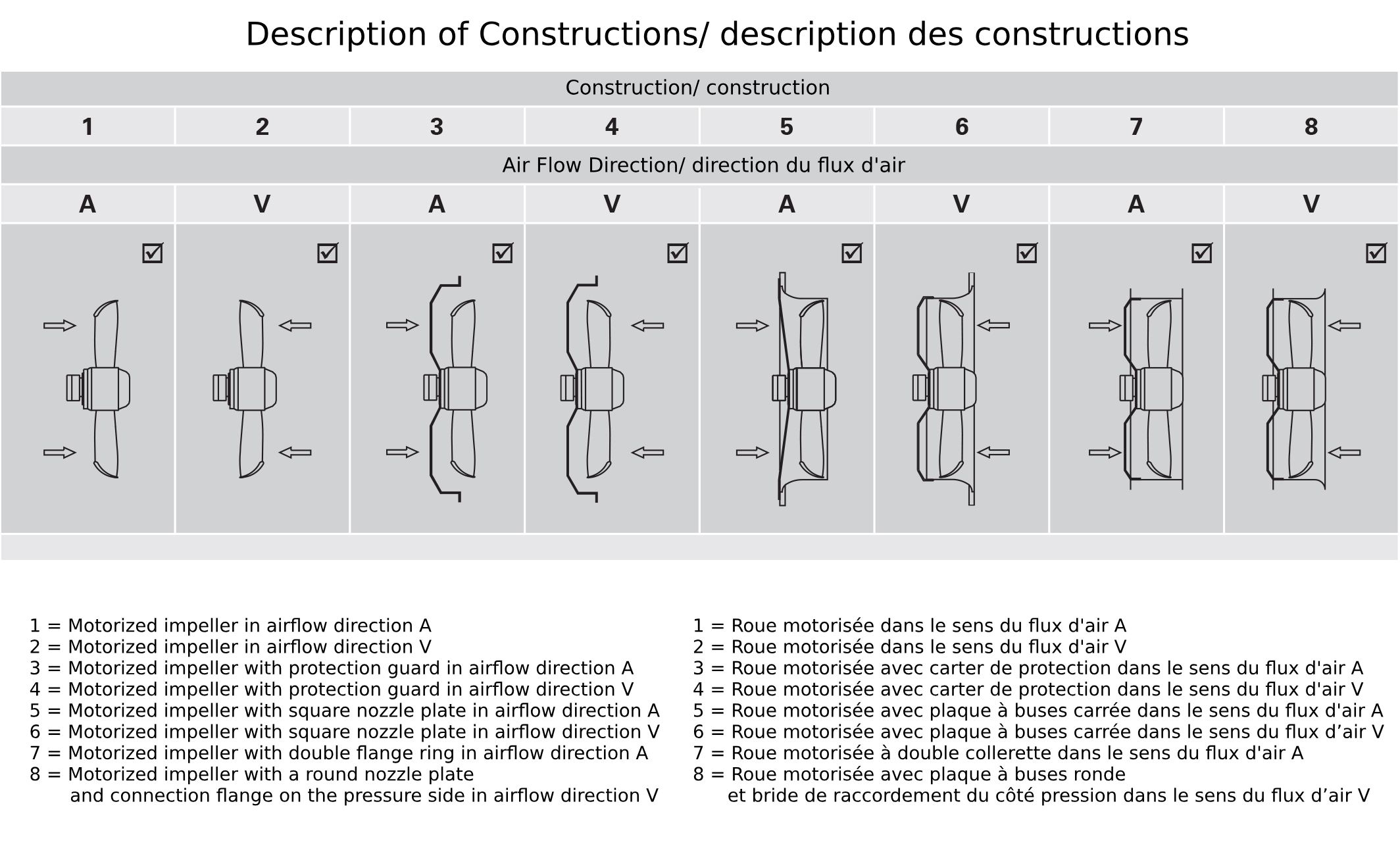

Description of Constructions