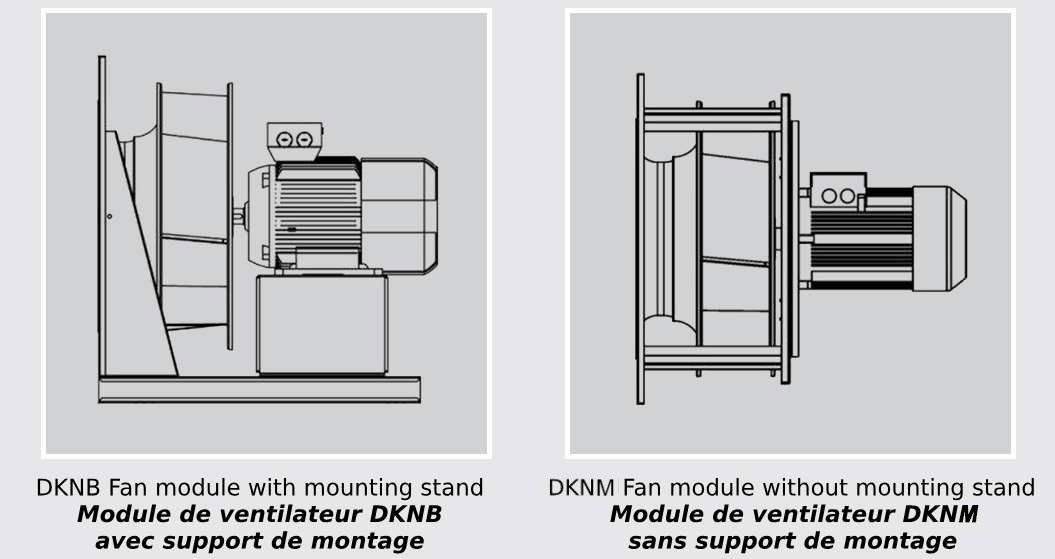

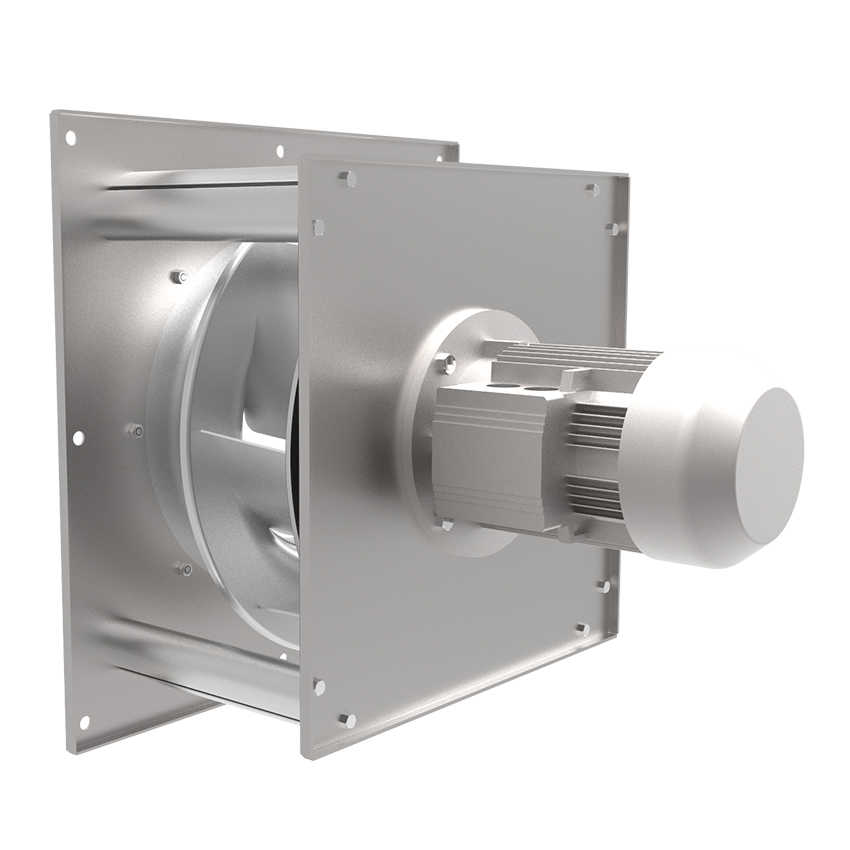

Features and Construction

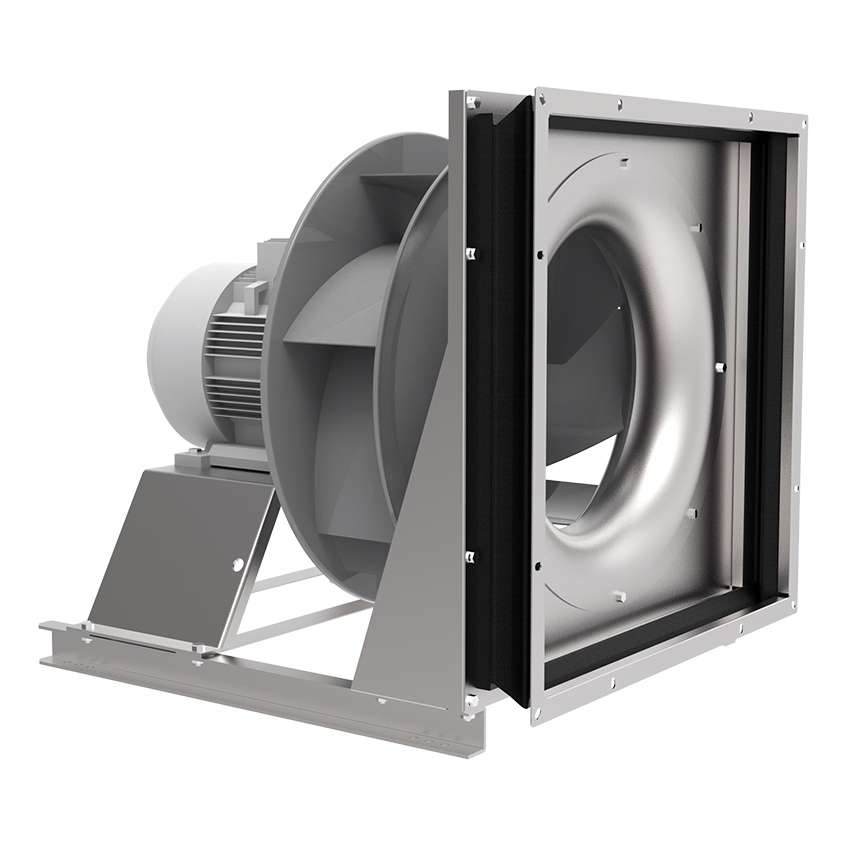

The Rosenberg Centrifugal Fans with a free-running impeller of the range DKN_ were designed to install appliances such as Air Handling Units (AHU), hygienic- and clean room filter units. During the development of this unit with a backward-curved impeller without scroll casing, special attention was paid to optimize the efficiency over a wide characteristic curve having at the same time high performance and an optimum sound power level. The fans are suitable to handle air and other non-aggressive gases or fumes. The motors are available with the latest three-phase IEC standard motors or standard NEMA Premium Efficiency motors. Moreover, different features depending on the application, such as explosion-proof or hazardous locations, are available. Depending on fan construction, the following two fan types are available: DKNB and DKNM.

DKNB:

Fan module with mounting stand.

The Inlet cone is mounted and adjustable to correct depth.

Complete unit installable with vibration dampers or springs.

Fan with NEMA PE motor, respectively with IEC standard motor; type IMB3.

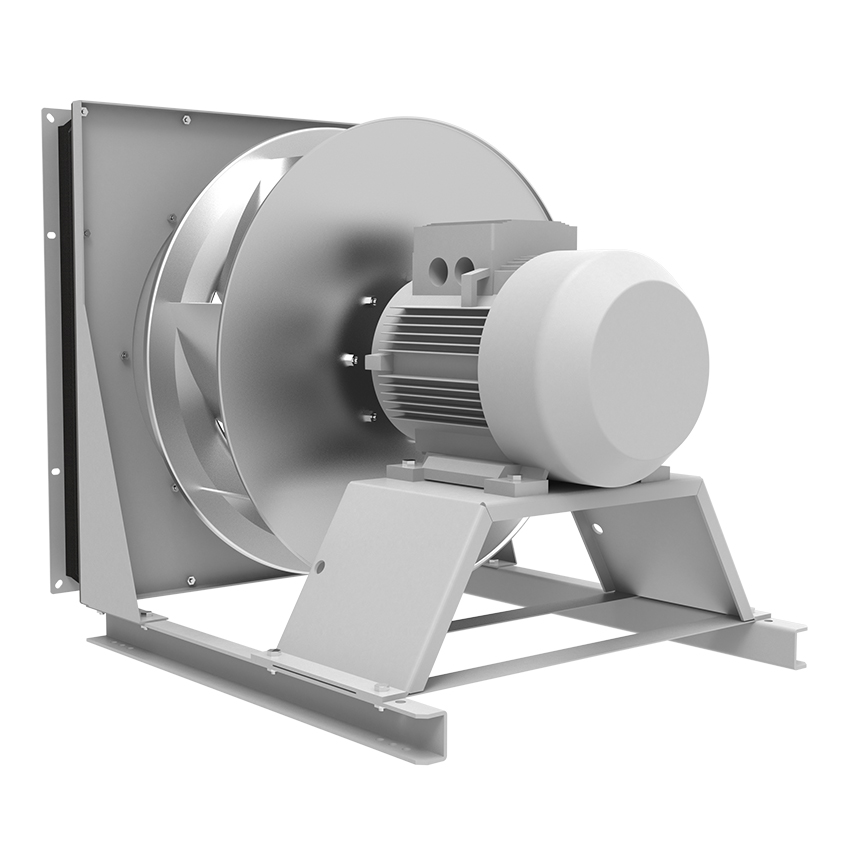

DKNM:

Fan module without mounting stand.

The Inlet cone is mounted and adjusted to the correct depth.

Fan with NEMA PE motor, resp. with IEC standard motor, type IMB5.

Advantages of radial fans with a free-running impeller

- Easy maintenance as a result of no fan belt abrasion or wear and tear

- Hygienic, easy to clean

- Can be installed either with a horizontal or vertical shaft (DKNB; DKNM)

- Compact, space-saving construction

- Easy determination of the airflow due to measuring device

- Technical decoupling of vibration of the module possible

- High economic efficiency as a result of the optimized efficiency of the impeller

Impeller

The impellers with 7 backward-curved blades are made of aluminum (AIMg3) and are statically and dynamically balanced with hubs according to quality level G6.3 DIN ISO 1940.

The impellers can be supplied with a special coating for harsh environments if needed.

Direction of rotation

The direction of rotation of the impellers (viewed from the inlet side) is clockwise.

The wrong direction of rotation can overload the motor; therefore, it is essential to check the direction of rotation before the initial operation.

Inlet cone

The inlet cones are made of galvanized sheet steel.

They are fluidic optimized and offer a good airflow of the impeller.

The optimal immersion depth of the impeller is shown according to dimensional drawings.

Airflow control and monitoring can be done through a circular lead on the inlet cone.

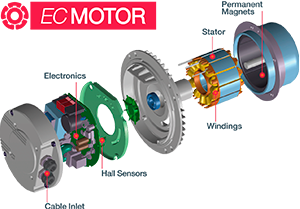

Motor

Rosenberg’s DKNM and DKNB fans are equipped with NEMA Premium Efficiency motors, 230V/460V/60Hz.

They can be supplied with the following options: partially or totally enclosed, explosion-proof, etc. In addition, different voltages are available and a different number of poles for different nominal speeds. Further information on the drive motor, motor safety, and speed control can be found in the individual special description of each ventilator type.

Electrical connection

The wiring box of the motor is easily accessible. The motor has to be connected according to the wiring diagram and under valid regulations and local laws.

In case of operation with frequency transformer, please refer to the operation manual.

Speed control

The installation-specific optimal adjustment for the required operating point can only be released with a suitable speed control system. The speed is changed by changing the frequency with a frequency converter. The maximum frequency of the motor must be observed. At higher frequencies than fmax, the motor will thermally overload, and the temperature sensor will react after a certain period of heating up. The cut-off frequency adjustable on the frequency converter is 50Hz for IEC standard motors and 60Hz for NEMA motors. In case of emergency service or failure of the frequency converter, all fans can be operated at 400V, 50Hz, respectively 460V, 60Hz, main supply. When a frequency converter operates the motors, the maximum speed of voltage increase of 500V/μs should not be exceeded.

Depending on the type of frequency converter and the length of the cable between the motor and frequency converter, additional components must be provided (e.g., a sinus filter).

title_en